A more affordable alternative is now available for non-contact thickness measurement of plastic films, medical membranes, glass tubing, and ophthalmic products.

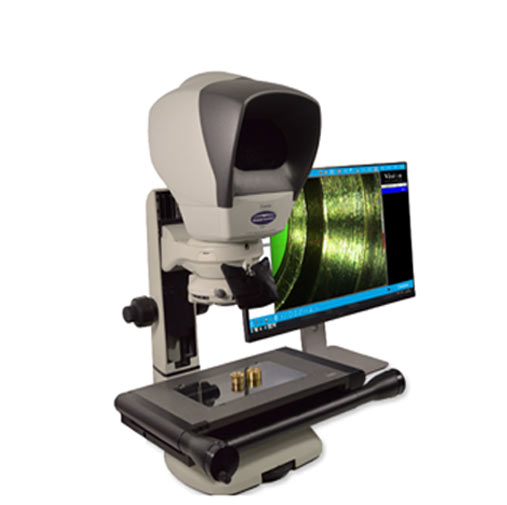

Bristol Instruments, Inc., a leader in optical interferometer-based instrumentation, has expanded its family of optical thickness gauge products. The new 137 Series Optical Thickness Gauge is a slightly modified version of Bristol’s industry-leading model 157. It has all the functionality, but it is intended for less exacting applications, measuring absolute thickness to an accuracy of ± 1 µm and with a repeatability of ± 0.05 µm.

The 137 Optical Thickness Gauge uses Bristol’s proven interferometer technology to measure thickness with light. This is a non-contact technique, resulting in the ability to measure both hard and soft materials without damage or deformation. In addition, all material layers are measured simultaneously. Therefore, the model 137 is the most convenient way to measure, for example, the critical dimensions of a glass tube – top wall thickness, bottom wall thickness, outer diameter, and inner diameter. The 137 system is also the best way to measure center thickness and sagittal height of contact and intraocular lenses.

“There are very few, if any, low-priced options for scientists and engineers who need precise thickness information,” said Dr. Brian Samoriski, President of Bristol Instruments. “But now, the 137 Optical Thickness Gauge provides this capability without depleting too much of a customer’s equipment budget.”

About Bristol Instruments

Since its founding in 2005, Bristol Instruments has focused solely on designing, manufacturing, and marketing precision instruments using its expertise in optical interferometry. Bristol’s flagship products accurately characterize the wavelength and spectral properties of lasers used by scientists and engineers at universities, government laboratories, and industrial laboratories. They are also used for the development and production testing of laser transmitters used in optical fiber communications. In addition, Bristol Instruments provides interferometer-based products to reliably measure critical physical dimensions of materials such as specialty plastic films, medical membranes, and ophthalmic products.

Source: www.bristol-inst.com